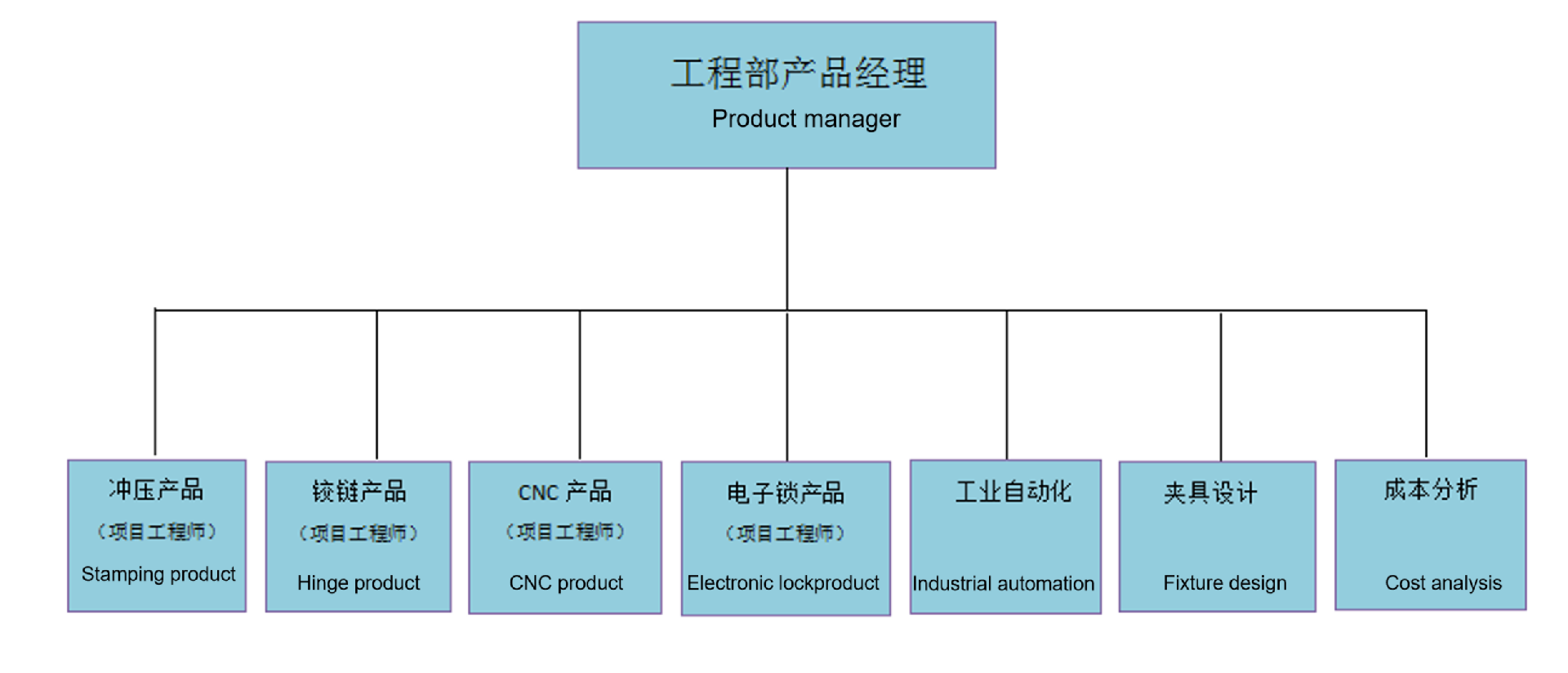

10名模具设计工程师致力于模具的设计和生产冲压技术的发展

Ten tooling design engineers are dedicated to tooling design and production of stamping technology development.

产品工程师被指定专门提供技术对客户的支持。

The product engineer is designated to provide technical support to the customer.

专业软件如PROE, UG, CAD, SOILDWORK等,确保了冲压、CNC模具、工装设计运行

Professional software such as PROE, UG, CAD, SOILDWORK etc. to ensure the stamping, CNC mold, tooling design and operation.

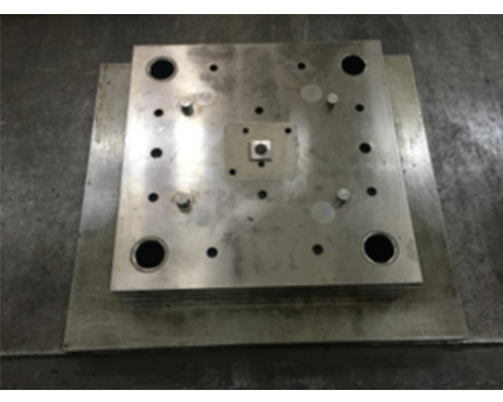

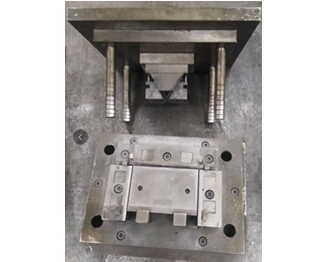

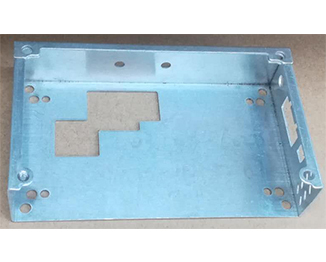

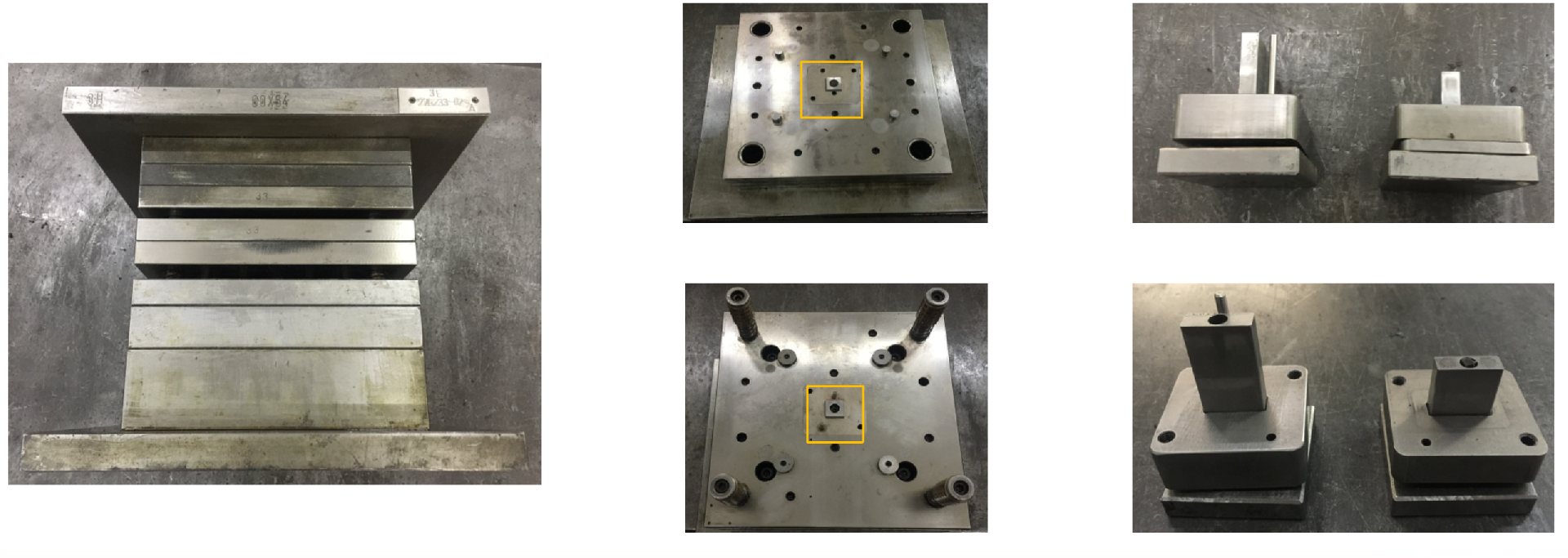

为确保更好的质量和加工精度,同时缩短制造周期,模具制造的工艺都是在公司内部完成。我们采用共用模架(更换模芯)、一模多穴等方式,协助客户降低成本。

In order to ensure better quality and processing precision, and shorten the manufacturing cycle, the mold manufacturing process is completed in the company. We use the common mold frame (replace the mold core), a mold multi-cavity and other ways to help customers reduce costs.

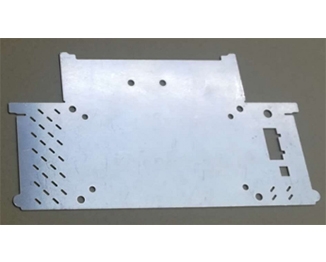

完善的检验流程:确保工具的每一部分都通过检验才能投入使用

Complete inspection process: ensure that every part of the tool passes inspection before it is put into use.

专业和经验丰富的工具制造商进一步保证在制造过程中符合技术要求。

Professional and experienced tool manufacturers further ensure that the manufacturing process meets the technical requirements.

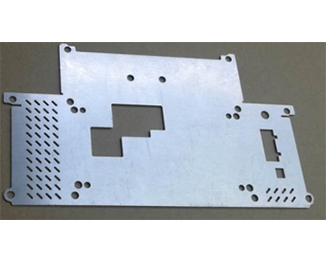

简化生产和标准化模具制造过程。

Simplify production and standardize mold manufacturing process.

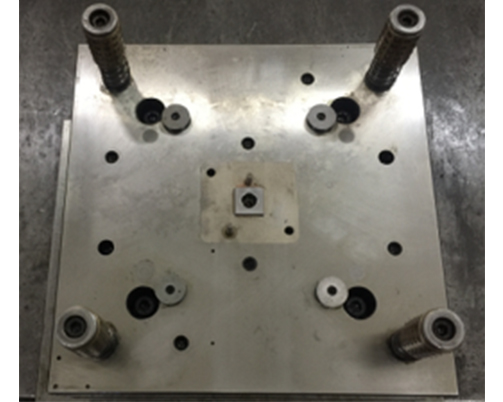

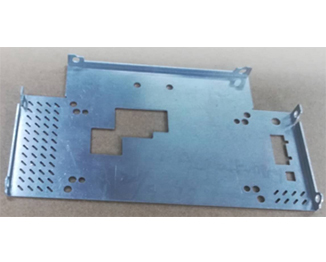

设备齐全的工具制造机床(30台)和强大的配套加工设施

Fully equipped tools manufacturing machine tools (30 sets) and powerful supporting processing facilities.

模具车间面积500平方米。

The mold workshop covers an area of 500 square meters.

月生产能力冲压五金模达60套

Monthly production capacity of stamping hardware mold reach 60 sets.